Operation of Synchronous Motor Drives

As soon as variable-frequency inverters became a practicable proposition it was natural to use them to supply synchronous motors, thereby freeing the latter from the fixed-speed constraint imposed by mains-frequency operation and opening up the possibility of a simple open-loop controlled speed drive.

The obvious advantage over the inverter-fed induction motor is that the speed of the synchronous motor is exactly determined by the frequency, whereas the induction motor always has to run with a finite slip.

A precision frequency source (oscillator) controlling the inverter switching is all that is necessary to give an accurate speed control with a synchronous motor, while speed feedback is essential to achieve accuracy with an induction motor.

In practice, open-loop operation of inverter-fed synchronous motors is not as widespread as might be expected, though it is commonly used in multi-motor drives.

Closed-loop or self-synchronous operation is however rapidly gaining momentum, and is already well established in two distinct guises at opposite ends of the size range.

At one extreme, large excited-rotor synchronous motors are used in place of d.c. drives, particularly where high speeds are required or when the motor must operate in a hazardous atmosphere (e.g. in a large gas compressor). At the other end of the scale, small permanent magnet synchronous motors are used in brushless d.c. drives.

We will look at these closed-loop applications after a brief discussion of open-loop operation.

Open Loop Inverter Fed Synchronous Motor Drives

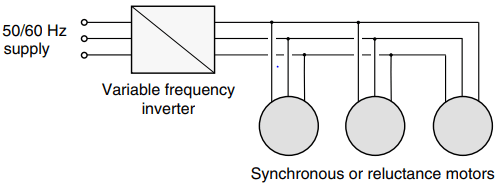

This simple method is attractive in multi-motor installations where all the motors must run at exactly the same speed. Individually the motors (permanent magnet or reluctance) are more expensive than the equivalent mass-produced induction motor, but this is offset by the fact that speed feedback is not required, and the motors can all be supplied from a single inverter, as shown in Figure 1.

The inverter voltage–frequency ratio will usually be kept constant to ensure that the motors operate at full flux at all speeds, and therefore have a ‘constant-torque’ capability. If prolonged low-speed operation is called for, improved cooling of the motors may be necessary.

Speed is precisely determined by the inverter frequency, but speed changes (including run-up from rest) must be made slowly, under ramp control, to avoid the possibility of exceeding the pull-out load angle, which would result in stalling.

A problem which can sometimes occur with this sort of open-loop operation is that the speed of the motor exhibits apparently spontaneous oscillation or ‘hunting’.

The supply frequency may be absolutely constant but the rotor speed is seen to fluctuate about its expected (synchronous) value, sometimes with an appreciable amplitude, and usually at a low frequency of perhaps 1 Hz.

The origin of this unstable behaviour lies in the fact that the motor and load constitute at least a fourth-order system, and can therefore become very poorly damped or even unstable for certain combinations of the system parameters.

Factors that influence stability are terminal voltage, supply frequency, motor time-constants and load inertia and damping. Unstable behaviour in the strict sense of the term (i.e. where the oscillations build-up without limit) is rare, but bounded instability is not uncommon, especially at speeds well below the base (50 Hz or 60 Hz) level, and under light-load conditions. It is very difficult to predict exactly when unstable behaviour might be encountered, and provision must be made to combat it.

Some inverters therefore include circuitry that detects any tendency for the currents to fluctuate (indicating hunting) and to modulate the voltage and/or frequency to suppress the unwanted oscillations.

Self-synchronous (closed-loop) Operation

In the open-loop scheme outlined above, the frequency of the supply to the motor is under the independent control of the oscillator driving the switching devices in the inverter. The inverter has no way of knowing whether the rotor is correctly locked-on to the rotating field produced by the stator, and if the pull-out torque is exceeded, the motor will simply stall.

In the self-synchronous mode, however, the inverter output frequency is determined by the speed of the rotor. More precisely, the instants at which the switching devices operate to turn the stator windings on and off are determined by rotor position-dependent signals obtained from a rotor position transducer (RPT) mounted on the rotor shaft.

In this way, the stator currents are always switched on at the right time to produce the desired torque on the rotor, because the inverter effectively knows where the rotor is at every instant of time. The use of rotor position feedback signals to control the inverter accounts for the description ‘closed-loop’ used above.

If the rotor slows down (as a result of an increase in load, for example), the stator supply frequency automatically reduces so that the rotor remains synchronised with the rotating field, and the motor therefore cannot ‘pull-out’ in the way it does under open-loop operation.

The overall operating characteristics of a self-synchronous a.c. motor are very similar to those of a conventional d.c. motor. The timing and direction of the current in each phase is governed by the inverter switching, which in turn is determined by the rotor position sensor.

Hence, regardless of speed, the torque is always in the right direction. The combination of the rotor position sensor and inverter performs effectively the same function as the commutator in a conventional d.c. motor.

There are of course usually only three windings to be switched by the inverter, as compared with many more coils and commutator segments to be switched by the brushes in the d.c. motor, but otherwise the comparison is valid.

Not surprisingly the combination of position sensor and inverter is sometimes referred to as an ‘electronic commutator’, while the overall similarity of behaviour gives rise to the rather clumsy term ‘electronically commutated motor’ (ECM) or the even worse ‘commutatorless d.c. motor’ (CLDCM) to describe self-synchronous machines.

Operating Characteristics and Control

If the d.c. input voltage to the inverter is kept constant and the motor starts from rest, the motor current will be large at first, but will decrease with speed until the motional e.m.f. generated inside the motor is almost equal to the applied voltage.

When the load on the shaft is increased, the speed begins to fall, the motional e.m.f. reduces and the current increases until a new equilibrium is reached where the extra motor torque is equal to the load torque.

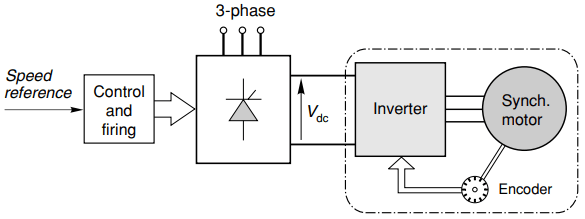

The speed of the self-synchronous motor can therefore be controlled by controlling the d.c. link voltage to the inverter. The d.c. link will usually be provided by a controlled rectifier, so the motor speed can be controlled by varying the input converter firing angle, as shown in Figure 2.

The overall similarity with the d.c. drive is deliberately emphasised in Figure 2. The dotted line enclosing the a.c. motor together with its rotor position detector and inverter is in effect the replacement for the conventional d.c. motor. Full four-quadrant operation is possible, as long as the inverter is supplied from a fully controlled converter.

Note, that a tachogenerator is not necessary for closed-loop speed control because the speed feedback signal can be derived from the frequency of the rotor position signal.

In simple cost terms the self-synchronous system looks attractive when the combined cost of the inverter and synchronous motor is lower than the equivalent d.c. motor.

When such schemes were first introduced (in the 1970s) they were only cost-effective in very large sizes (say over 1 MW), but the break-even point for wound-field motors is falling and drives with ratings in the hundreds of kW are now common.

They may utilise converter-grade (relatively cheap) thyristors in the inverter bridge because the thyristors will commutate naturally with the aid of the motor’s generated e.m.f. At very low speeds, however, the generated e.m.f. is insufficient, so the motor is started under open-loop current-fed operation.

As inverter costs have fallen, lower power drives using permanent magnet motors have become attractive, especially where very high speeds are required and the conventional brushed d.c. motor is unsuitable because of commutator limitations.